|

个人信息Personal Information

教授

硕士生导师

教师拼音名称:Liang Yingzong

入职时间:2018-12-27

所在单位:材料与能源学院

联系方式:yliang@gdut.edu.cn

在职信息:在职

主要任职:Professor

其他任职:Professor

毕业院校:The Hong Kong University of Technology

学科:工程热物理

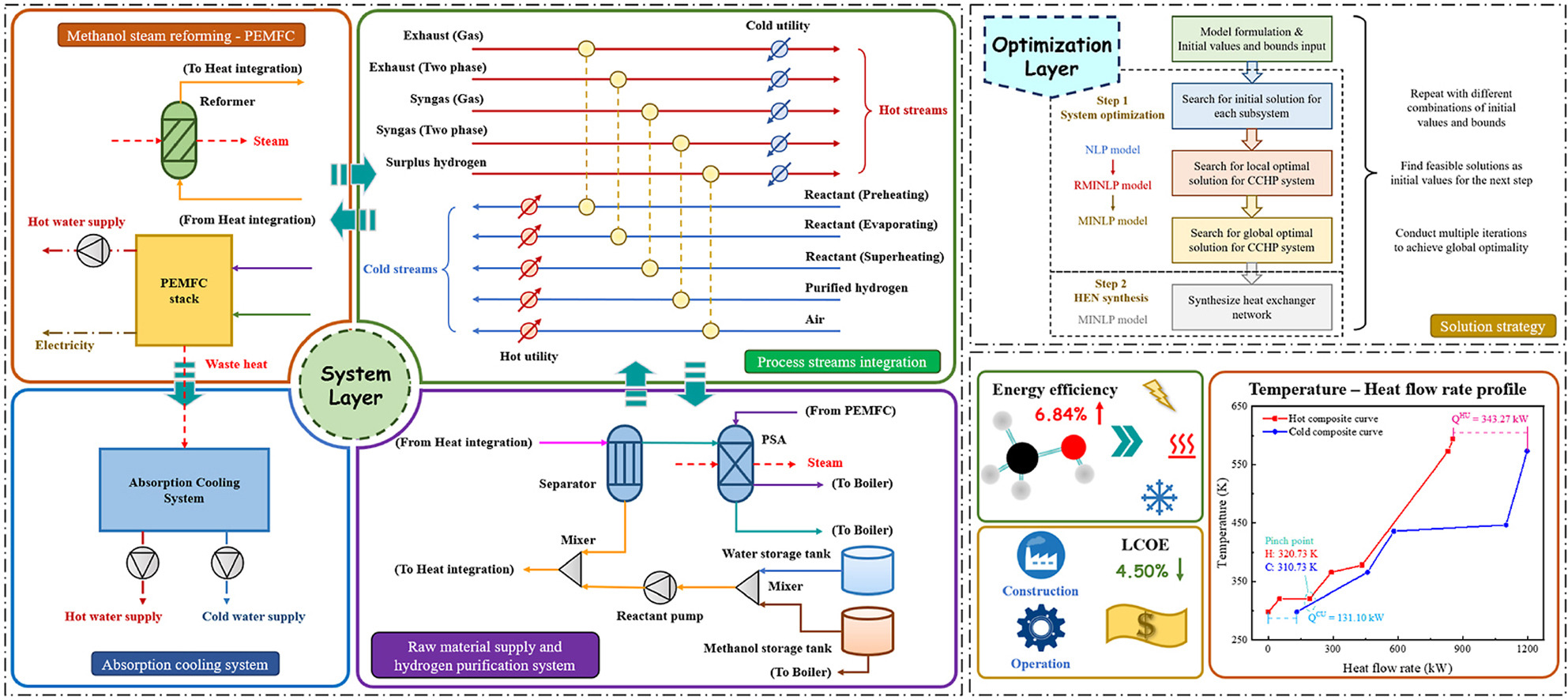

Integration and optimization of methanol-reforming proton exchange membrane fuel cell system for distributed generation with combined cooling, heating and power

点击次数:

影响因子:11.1

DOI码:10.1016/j.jclepro.2023.137342

发表刊物:Journal of Cleaner Production

摘要:The methanol-steam-reforming proton exchange membrane fuel cell system is an attractive option for distributed cogeneration due to its low emissions, quiet operation, and low-cost fuel storage. To further increase its energy efficiency, waste heat can be utilized for combined cooling, heating, and power generation. However, the additional equipment, processes, and streams required for cogeneration make the system design complex, with a large number of degrees of freedom. To address this challenge, we propose an equation-based optimization framework for the simultaneous heat integration and flowsheet optimization of the combined cooling, heating, and power system based on the methanol-steam-reforming proton exchange membrane fuel cell. The framework comprises a detailed modelling of methanol steam reforming reaction, fuel cell performance, cooling/heating cogeneration systems, heat integration, heat exchanger network synthesis and energetic-economic performance evaluation. Additionally, the framework incorporates the sizing of the corresponding equipment, including the total length of the reformer, scale of proton exchange membrane fuel cell stack, and absorption cooling apparatus. Furthermore, it takes into account the operating conditions, such as the temperature and pressure of methanol steam reforming reaction, the operating temperatures and pressures of the fuel cell stack and absorption cooling system. We apply the framework to a 1000 kWe combined cooling, heating, and power generation system, and the integrated design achieved an energy efficiency of 88.50% and a levelized cost of electricity of 0.2374 $/kWh. The results show that the simultaneous heat integration and flowsheet optimization can increase the system's energy efficiency by 5.45 percentage points, exergy efficiency by 2.22 percentage points, and decrease the levelized cost of electricity by 4.50% compared to a conventional design.

合写作者:Huasheng Wang,Wei Wu,Jianyong Chen,Ying Chen

第一作者:Zheng Liang

论文类型:期刊论文

通讯作者:Yingzong Liang,Xianglong Luo

卷号:411

页面范围:137342

是否译文:否

发表时间:2023-07-20

收录刊物:SCI